High-Performance doors for Industrial, Commercial, Pharmaceutical and Cold-Storage Environments. Whether they’re rolling, folding or sliding doors, high-performance doors are our only business.

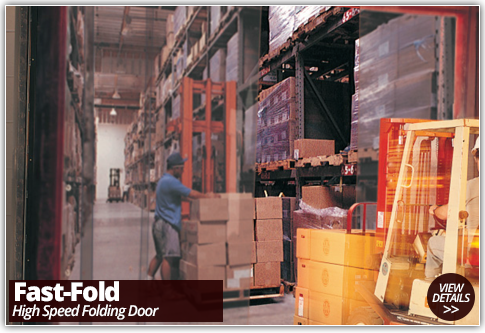

Fast-Fold

America's First Break-Away Door. And Still a Workhorse.

With its natural ability to withstand forklift impact without sustaining damage, the Fast-Fold door introduced the Break-Away™ concept to the United States in 1985.

It can be used almost anywhere, for interior, exterior, warehousing, manufacturing or commercial applications. Because of the many patented, proven design features like its rugged Tec-Trak™ and floating Ryflex™ roller system, it provides millions and millions of cycles of dependable service.

Fast - Opens at up to 84 inches per second for improved traffic flow.

Threshold Safety - With its full height, clear PVC panels, the Fast- Fold provides great visibility and added safety for interior applications where fork trucks and other equipment are crossing the threshold in both directions, crossing the door’s traffic lane, or both.

Energy Efficient - Overlapping Puralon™ panels with rope tie panel connectors offer a great seal to dramatically reduce energy loss.

Durable, Low Maintenance - Engineered to last millions of cycles with minimum maintenance.

Takes a Hit - Withstands fork truck impact with little or no damage, virtually eliminating down time.

Easy Installation - Modular construction and easy to hang panel mounting hardware allow for quick and easy installation.